ExSpurt Tires

ExSpurt’s wheels are simple and easy to make. All you need is a lathe! I can turn out eight wheels in one very relaxing evening and I an a beginner with machine tools. Start with a 1” diameter 7075 aluminum rod with about 2” protruding from a three jaw chuck. Turn the OD down to .700”, finish cut the end, and drill a 3mm hole down the middle for the axle. Cut off about an inch of turned material. Repeat the process seven more times. ExSpurt’s wheels are simple and easy to make. All you need is a lathe! I can turn out eight wheels in one very relaxing evening and I an a beginner with machine tools. Start with a 1” diameter 7075 aluminum rod with about 2” protruding from a three jaw chuck. Turn the OD down to .700”, finish cut the end, and drill a 3mm hole down the middle for the axle. Cut off about an inch of turned material. Repeat the process seven more times.

Mount a 5/8 inch end mill in a tool holder on the carriage and bore out the insides of each wheel such that there is .250” left for the hub area. The hole in the wheel actually comes out to about .605” diameter. Then finish cut the end so that the wheel is .950” long. Drill and tap a 4-40 threaded hole for the axle set screw. Clean up the 3mm axle hole, the 4-40 thread, and install 4-40 set screw. One important step is to scratch two lines on the wheel’s outer face to locate the set screws. There, eight new wheels in one evening. |

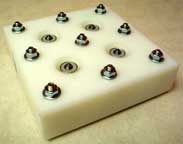

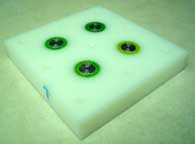

The tire mold is made of two 6” square pieces of HDPE. The bottom piece is .5” thick and the top piece is 1” thick. Clamp the two pieces in a mill with a thin piece of waste material between the two. Drill the nine .250” bolt holes while placing a bolt in each hole as it is drilled to hold the alignment. Bore each 1.000” tire hole down to the waste material. In previous tire molds, the center hole in the bottom piece was drilled at the same time as the tire bore, but the waste material deflected the 3mm drill enough to cause noticeable wobble in the first set of wheels. So, I drilled a 3mm center hole in a piece of 1” diameter aluminum and used that as a drill guide in the tire bore after the waste material was removed. Make sure to mark the bottom and top halves of the mold so that they go together the same way every time. The tire mold is made of two 6” square pieces of HDPE. The bottom piece is .5” thick and the top piece is 1” thick. Clamp the two pieces in a mill with a thin piece of waste material between the two. Drill the nine .250” bolt holes while placing a bolt in each hole as it is drilled to hold the alignment. Bore each 1.000” tire hole down to the waste material. In previous tire molds, the center hole in the bottom piece was drilled at the same time as the tire bore, but the waste material deflected the 3mm drill enough to cause noticeable wobble in the first set of wheels. So, I drilled a 3mm center hole in a piece of 1” diameter aluminum and used that as a drill guide in the tire bore after the waste material was removed. Make sure to mark the bottom and top halves of the mold so that they go together the same way every time.

Four additional pieces of HDPE were turned to fit inside the wheels to help hold and align everything during molding. Don’t forget the next step! With the set screws in the wheels, fill up the rest of the threaded hole with Vaseline. Put a good sized glob of Vaseline inside the wheels and bolt everything together. Note: mold release isn’t required on HDPE. |

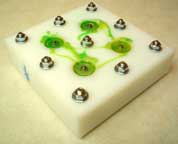

I use polyurethane mold rubbers from Polytek, either 74-20 or 74-30 with part C added for softer tires. Mix up enough for four wheels according to the instructions. I do not degas the mixture and have not had a problem with air bubbles. To add some color, drip in four or five drops of color (I use green), swirl around a little and pour. The green gives a nice marbled effect or mushy sick appearance, depending on your point of view. Be careful with the color from Polytek, one spilled drop and your house will be all green for a year. I use polyurethane mold rubbers from Polytek, either 74-20 or 74-30 with part C added for softer tires. Mix up enough for four wheels according to the instructions. I do not degas the mixture and have not had a problem with air bubbles. To add some color, drip in four or five drops of color (I use green), swirl around a little and pour. The green gives a nice marbled effect or mushy sick appearance, depending on your point of view. Be careful with the color from Polytek, one spilled drop and your house will be all green for a year.

After the polyurethane is mixed and swirled, pour smoothly into the mold. Work quickly because the stuff sets up fast. |

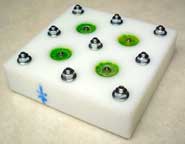

After the polyurethane cures for an hour or two, wipe up the spilled excess from the mold surface. It comes up easily at this stage. After the polyurethane cures for an hour or two, wipe up the spilled excess from the mold surface. It comes up easily at this stage. |

Go do something else for 24 to 48 hours. The longer you wait the better. When you can not wait any longer, unbolt and separate the mold halves. Wipe up excess polyurethane that squeezed between the mold joint. Go do something else for 24 to 48 hours. The longer you wait the better. When you can not wait any longer, unbolt and separate the mold halves. Wipe up excess polyurethane that squeezed between the mold joint. |

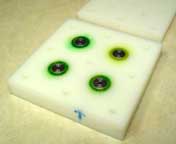

Run a .032” wire between the tire and mold while pushing on the wheel. The tires pop out easily. Now you have four ugly tires. Run a .032” wire between the tire and mold while pushing on the wheel. The tires pop out easily. Now you have four ugly tires.

The next step is to super glue the tires to the wheels. Starting with the inside of the tire, separate the tire from the wheel and squeeze in some regular (not gel) super glue. Hold the tire to the wheel until the super glue sets up. Let it cure for awhile. Do the same thing to the outside of the tire. |

After the super glue has cured, mount a wheel on an arbor and chuck in the lathe. Turn the wheels at about 1000 rpm and use a piece of 60 grit sand paper to finish the sides and surface of the tires. I like to round the tire edges at this time. After the super glue has cured, mount a wheel on an arbor and chuck in the lathe. Turn the wheels at about 1000 rpm and use a piece of 60 grit sand paper to finish the sides and surface of the tires. I like to round the tire edges at this time. |

Use the scratched alignment marks to poke an Allen wrench through the tire into the set screw hole. With a little luck the Allen wrench should find the set screw hole and then the set screw. Ball end Allen wrenches seem to work better in this application. Use the scratched alignment marks to poke an Allen wrench through the tire into the set screw hole. With a little luck the Allen wrench should find the set screw hole and then the set screw. Ball end Allen wrenches seem to work better in this application. |

I’ve made tires of Shore A 10, 20 and 30 for ExSpurt. So far, the Shore A 20 has tested the best on the Exert-O’Meter. With ExSpurt weighting in at 430 grams, a high of 1080 grams of push was recorded. The Shore A 10 tires bounced too much and the Shore A 30 tires just spun. I’ve made tires of Shore A 10, 20 and 30 for ExSpurt. So far, the Shore A 20 has tested the best on the Exert-O’Meter. With ExSpurt weighting in at 430 grams, a high of 1080 grams of push was recorded. The Shore A 10 tires bounced too much and the Shore A 30 tires just spun. |